Blog

Rotational Moulding – Which materials?

Polymers used in the rotational moulding process are manufactured in powder form and designed to have a consistent particle size and shape (typically 35 mesh) which helps to ensure even melting and coating of the mould.

The powders are also typically formulated with additives, such as UV stabilizers and colourants, to enhance the properties and appearance of the finished product.

There are a number of materials available, each with their own specific engineering properties, which should be taken into consideration for the suitability and application of the end product.

1. Polyethylene (PE): This is the most widely used material for rotational moulding, it is a thermoplastic polymer that is known for its durability, resistance to chemicals, and flexibility. PE is available in various grades and densities, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). This is the most commonly used material within the industry and used to manufacture many products that the public will come across in their everyday lives, such as road cones, road barriers, litter bins, grit salt bins etc.

2. Polypropylene (PP): This is another common material used in roto-moulding. It is a thermoplastic polymer that has good impact resistance, flexibility, and resistance to chemicals. Tanks, pipes and various vessels are manufactured from this material.

3. Nylon (PA): This is a synthetic thermoplastic material that is known for its toughness, high strength, and resistance to abrasion. It is commonly used in the production of industrial parts.

4. Ethylene Vinyl Acetate (EVA): is a type of thermoplastic material that is known for its softness, flexibility, durability, and rubber-like composition. It is a popular choice for manufacturers who want to create products that are lightweight, impact-resistant, and easy to clean. EVA is used in rotational moulding to produce a variety of products, such as road bollards, go-kart pods and children's toys.

5. Polyvinyl Chloride (PVC): This is a thermoplastic polymer that is known for its chemical resistance, durability, and flexibility. It is commonly used in the production of toys, medical equipment, and construction materials.

6. Polyurethane Foam (PU): Polyurethane foam is a popular choice for rotational moulding because of its excellent insulation and cushioning properties. It is commonly used to produce products such as: canoes, defibrillator cabinets, marine buoys, cool boxes, furniture, and toys.

The above list is by no means exhaustive and there are further polymers used within the industry, such as polycarbonate and cross link polyethylene, which can be moulded under specific conditions.

Overall, rotational moulding powders play a critical role in the manufacturing process, as they determine the quality, strength, and durability of the final product.

Rotational Moulding – What Products?

At Innovate Mouldings we manufacture a wide range of products for use in a variety of applications spread across the industrial spectrum.

Rotational moulding, also known as roto-moulding, is a versatile manufacturing process which in the early years of the sector, was mainly utilised to manufacture cylindrical containers and water tanks.

As the sector has developed and modernised with regards to machinery, design, materials and moulds, the process is now used to manufacture products that most people will use and come across in their everyday lives.

Here are some examples of products that can be made using rotational moulding:

Water tanks and containers: Rotational moulding is commonly used to produce water tanks, water butts, compost bins, domestic heating oil tanks, IBC’s and containers of various sizes and shapes for agricultural, industrial, and residential use.

Toys and playground equipment: The process is ideal for manufacturing toys and playground equipment, such as slides, sand pits, swings, and ride-on toys, due to its ability to produce complex shapes and designs.

Automotive parts: Rotational moulding is used to produce automotive parts, such as fuel tanks, air ducts, housings, washer bottles, mud guards and seat backs, due to its ability to produce large and complex shapes in a single piece.

Industrial containers and storage solutions: Widely used to produce industrial containers, such as storage bins, food grade containers, pallets, bottle trolleys, recycling bins and waste bins, due to its excellent durability, impact resistance, and chemical resistance.

Medical equipment and devices: Defibrillator cabinets, first aid boxes, hospital bed pans, kidney dishes, commode seats and other medical supplies, due to its ability to produce smooth, seamless surfaces that are easy to clean and sterilize.

Sporting goods and equipment: Boats, kayaks, canoes, golf carts, bike racks, helmets, and protective gear, due to its ability to produce large and complex shapes that are lightweight, durable, and impact resistant.

Road Barriers and Cones: Street and highway safety solutions such as barriers, road cones, grit salt bins and hoppers, bollards, portable toilets and signage. The process provides product durability and longevity, with many items of roto-moulded street furniture having been in use for many years, sometimes decades, out in the field.

Overall, rotational moulding offers a wide range of design possibilities and material choices, making it a popular choice for producing high-quality, durable, and complex parts and products for various industries.

If you have a product or project you would like us to review and advise upon, or you are a company with existing moulds, and looking for a manufacturer to produce for you, please feel free to contact us and we will be happy to help.

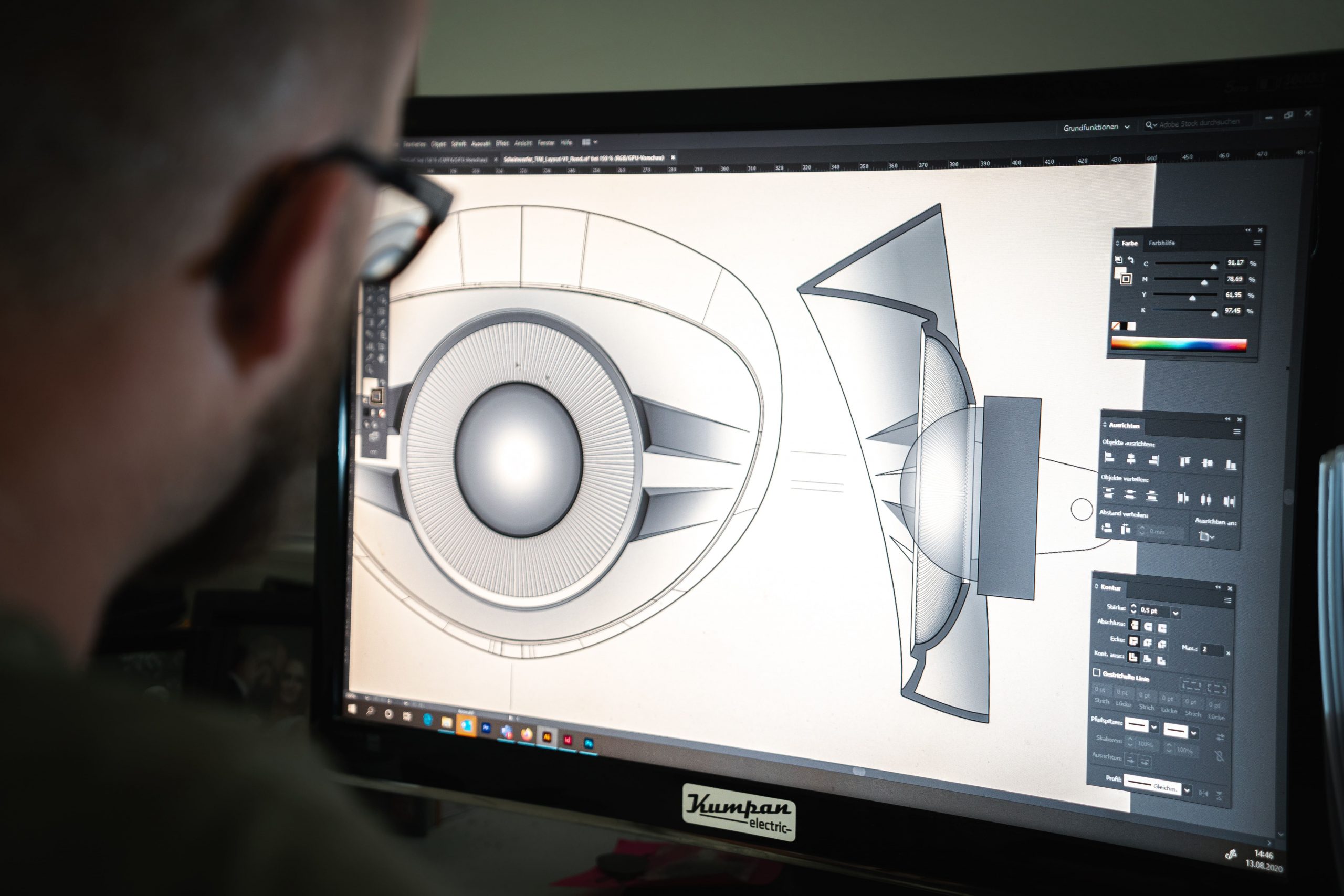

Design for Rotational moulding

Design plays a critical role in the success of rotational moulding. The design of the part must take into account the properties of the material, the moulding process, and the desired end-use. Here are some important considerations for rotational moulding design:

- Wall thickness: The wall thickness of the part should be consistent throughout to ensure even heating and cooling during the moulding process. Varying wall thickness can cause warping and deformation.

- Draft angles: Draft angles are used to allow the part to be easily released from the mould. A draft angle of at least 1 degree per inch of wall thickness is recommended to ensure proper release.

- Ribs and gussets: Ribs and gussets can be used to reinforce the part and prevent warping. They should be designed to allow for even heating and cooling during the moulding process.

- Undercuts: Undercuts can make it difficult to release the part from the mould. They should be avoided or designed to allow for easy release.

- Mouldability: The part should be designed to be easily moulded using the rotational moulding process. This includes avoiding sharp corners or edges, designing parts with a uniform thickness, and ensuring that the part is balanced and symmetrical.

- Materials: The material used for the part must be compatible with the rotational moulding process. It should also be able to meet the desired end-use requirements, such as strength, flexibility, and durability.

Eco Friendly Plastics – Developments

Over the past few decades, there has been a growing concern over the impact of plastic waste on the environment. Traditional plastics are non-biodegradable and can take hundreds of years to decompose. As a result, the world has seen a shift towards more eco-friendly plastic alternatives that are sustainable and biodegradable. Here are some of the latest developments in eco-friendly plastics:

Bioplastics

Bioplastics are made from renewable biomass sources such as corn starch, sugarcane, and potatoes. They are biodegradable and can decompose within a few months. Bioplastics can be used for a wide range of applications, including packaging, disposable cutlery, and even in the automotive industry. Bioplastics are still in the early stages of development and face challenges such as cost and scalability.

Bio-based plastics

Bio-based plastics are made from renewable biomass sources, but unlike bioplastics, they are not biodegradable. Instead, they can be recycled and reused, making them a more sustainable alternative to traditional plastics. Bio-based plastics can be used for a wide range of applications, including packaging, electronics, and automotive parts.

Compostable plastics

Compostable plastics are designed to break down into organic matter when they are disposed of in a composting environment. They are typically made from plant-based materials such as corn starch, potato starch, and sugarcane. Compostable plastics are becoming increasingly popular for food packaging and disposable cutlery. However, they can only be composted in industrial composting facilities and not in home composting systems.

Recycled plastics

Recycled plastics are made from post-consumer or post-industrial waste. They are a sustainable alternative to traditional plastics as they reduce the amount of waste that ends up in landfills. Recycled plastics can be used for a wide range of applications, including packaging, furniture, and construction materials.

Biodegradable additives

Biodegradable additives are added to traditional plastics to help them break down more quickly. These additives are typically made from natural materials such as corn starch, potato starch, and sugarcane. While biodegradable additives can make traditional plastics more sustainable, they are not a complete solution as they still produce microplastics that can harm the environment.

In conclusion, there are many eco-friendly plastic developments that can help reduce the impact of plastic waste on the environment. However, it is important to remember that no single solution is perfect, and a combination of these alternatives is needed to create a more sustainable future.

Innovate Mouldings UK Ltd – Our Aim

At Innovate Mouldings UK Ltd we recycle 100% of our in-house scrap polymer for re-use in the manufacture of a wide range of products, utilising the Rotational Moulding process. Many of our customers specifically request products manufactured from 100% recyclable polymer, which subsequently provides them with a higher valued product. Eco friendly plastics are made up of varieties and grades that are very specific to certain plastic manufacturing processes, as the science develops and more grades become available that are compatible for use within the Rotational Moulding process, we aim to be at the forefront of utilising these new materials, to manufacture products that not only reduce waste, CO2 emissions and pollution but overall, much more environmentally friendly.

Sheffield Business Award – Manufacturing

The last week in September proved quite a week for our group of companies: The Poly Group.

Whilst the management team were busy manning the stand at the Interplas UK Exhibition at the Birmingham NEC, our director, Julie Garner was busy attending The Star Sheffield local business awards, of which we won The Small Business Manufacturing Award! Having had a successful exhibition, Julie promptly drove down to the NEC to have a celebratory night out with the management team, and what a celebration it was! We are thrilled to have won the award, after what have proven to be, some of the most difficult couple of years for businesses throughout the UK and we would like to thank all the members of our team for the resilience shown and dedicated hard work, of not only, ensuring the company has operated to the best of its capabilities, but also, winning an award in the midst of it all. The Poly Group comprises of: Innovate Mouldings UK Ltd, Poly Plas Engineering Ltd, Poly Truck, Pedigree Pools and Viper Vivs.